Corporate Profile

Overview

MJ SURGICAL is India’s leading manufacturer, Supplier and exporter of orthopaedic Implants & Instruments based at Ahmedabad, Gujarat Since 1998.

MJ SURGICAL has been able to establish its name as one of the most preferred and trusted brands by healthcare experts and vendors across the world. Our range and quality of the products have earned us the global repute and recognition in orthopaedic implants and instruments.

MJ SURGICAL aims at providing world class orthopaedic implants and instruments at the affordable cost.

Management

Our team comprises highly motivated members like engineers, designers, product developers, machine operators, marketing team, logistics team, quality control team, R & D team, consultants and more!

Our senior management believes in the philosophy of driven by patients, focused by medical practitioners. We have always tried to develop products with international standards within the criteria of affordability.

Be it the top most management or the youngest member of the MJ family, one thing is common in all of us: ‘passion to achieve more and more milestones that makes the lives of patients healthier and happier day by day, minute by minute, moment by moment!’

Technology and Manufacturing Process

It is our goal to provide the best in quality and value to every individual. Consistency is a virtue we pursue with a passion. From the procurement of raw materials to the manufacturing of orthopaedic implant and instruments, we employ world-class systems and technology on par with the highest standards of globally recognised evaluation systems.

Raw Material

All our raw material is sourced internationally from top quality providers. Special attention is paid to storage of sensitive material and is done according to appropriate ISO standards amongst other international safety and hygiene assessments.

Our implants are made of stainless steel, titanium alloys and PEEK. The materials are tested for biocompatibility and safety according to EN ISO 10993 and EN ISO 14971. The chemical composition, mechanical properties, and the purity of the microstructure meet the requirements specified by international standards.

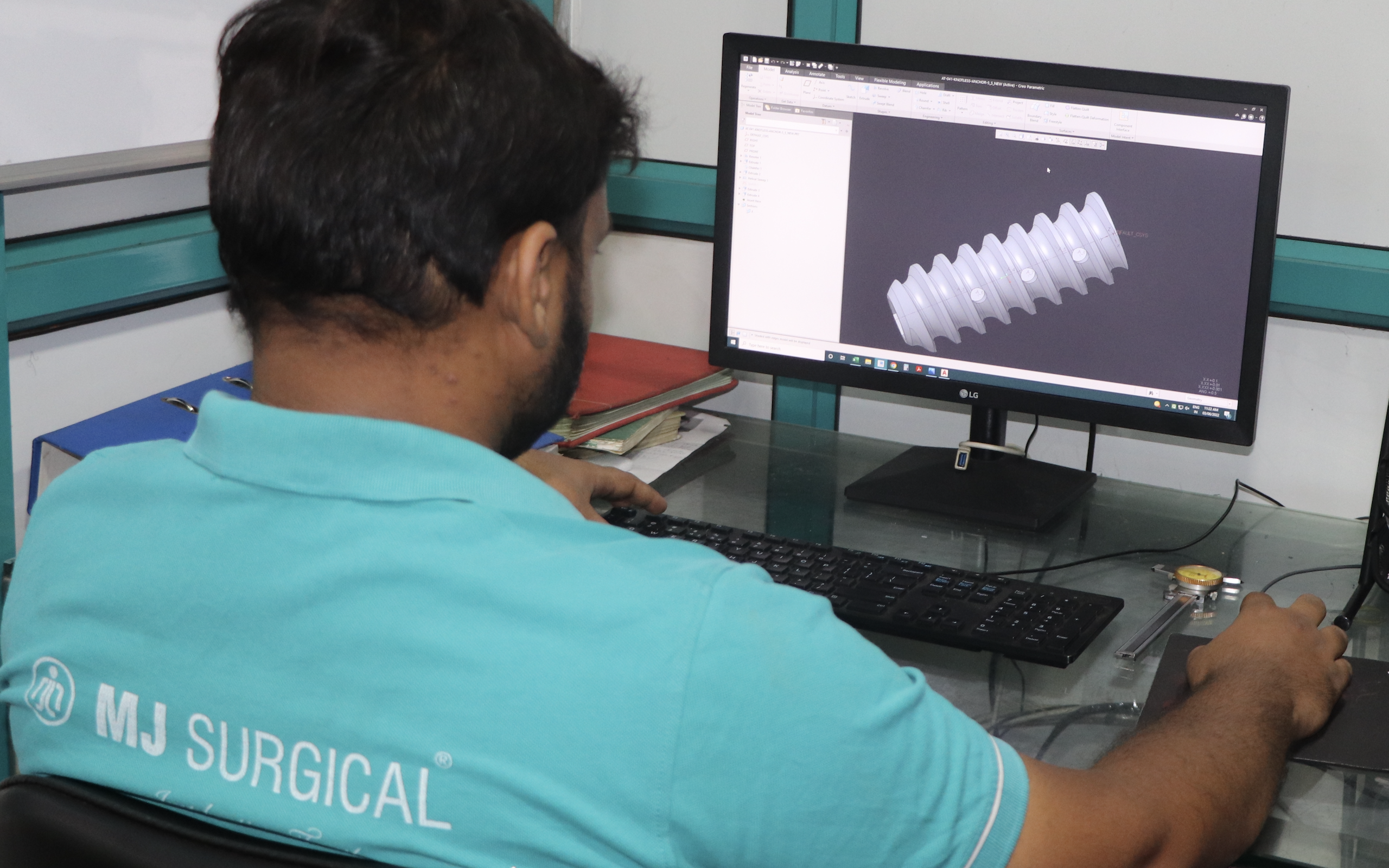

Computer-Aided Manufacturing

We employ world’s best CAD software PTC Creo and CAM software Mastercam to provide the most effective solutions to our clients

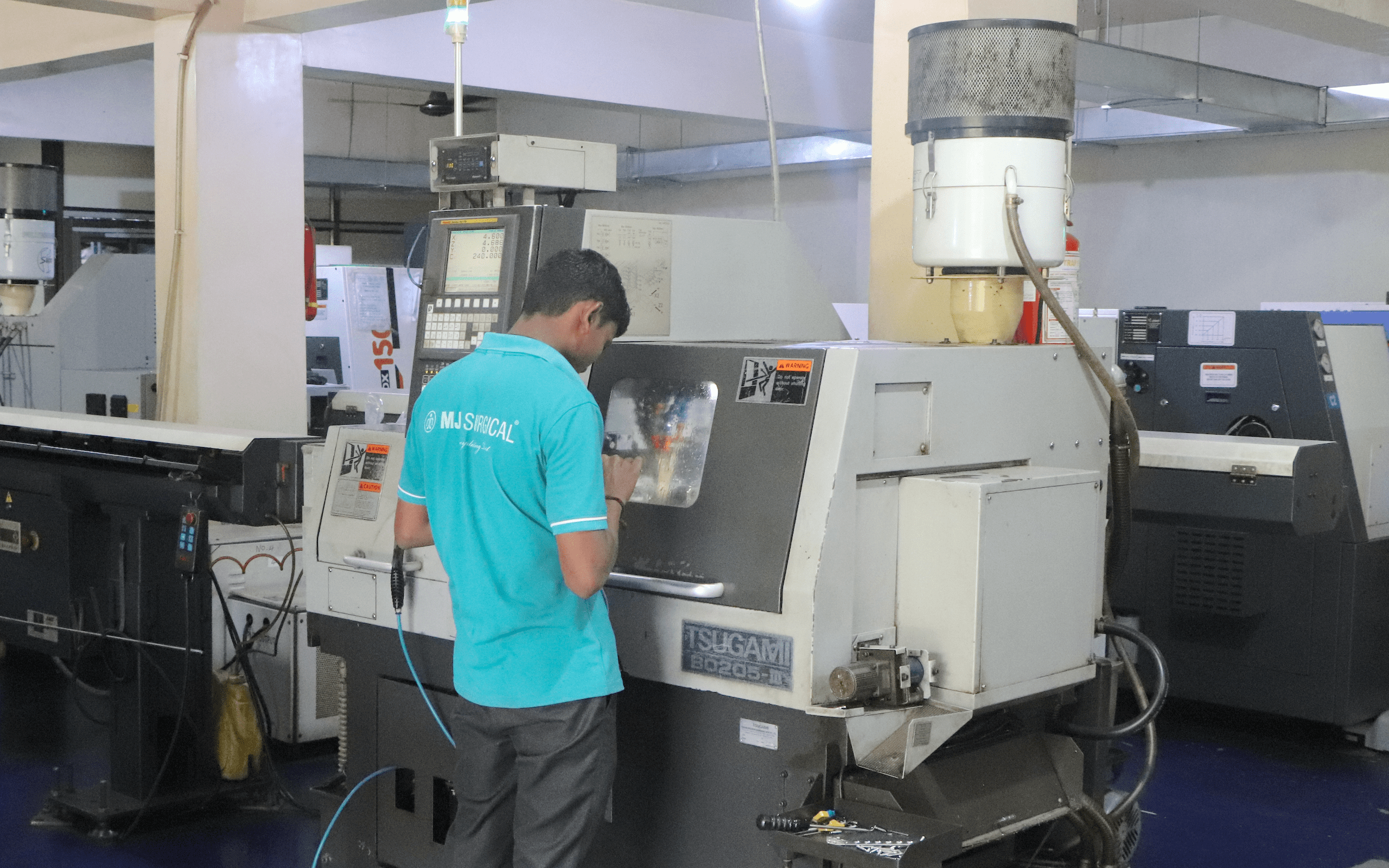

Production Capabilities

Our manufacturing unit comprises of the latest machineries imported from across the world. We are using CNC Mill Turn, CNC Multi-axis, CNC Sliding Head, VMC Multi-axis, CNC Turning, Wire EDM, Automated Buffing, Sand Blasting, Electropolishing, Titanium Anodizing, Ultrasonic Cleaning, and Laser Marking Machines.

Sterilization and Clean Room Packaging

Fully Automatic ETO Sterilization machine installed in our facility;

Our clean room meet requirement of ISO 14644, ISO Class 7 Clean Room Packaging, ISO Class 8 Air-Shower, ISO Class 5 Dynamic Pass Boxes and Laminar Air Flow available in it.

In-House testing lab fully equipped to do all kind of testing along with Stability Studies;

Our facilities are equipped to carry out every stage of sterile and non-sterile packaging operations with maximum speed and minimum error. Every single product is sealed in pouches and labelled according to international standards.

Director's Statement

MJ SURGICAL is globally represented by self or through our appointed representatives. We have been exporting our products to Europe, America, Africa, Asia and other major parts of the world. Nationally we cover almost all corners of the country. Export inquires are generated from various parts of the world for supply of different types and wide range of MJ SURGICAL products made out of exclusively products range.

Presently the global market situation is being assessed and the strategy is reorganized to suite the demands of the global requirement.One can find MJ SURGICAL at almost all leading national and international level seminars, conferences, exhibitions, conventions, gatherings and all type of ortho implant manufacturing related words and venues.

Certifications

MJ Surgical maintains a quality management system which is regularly certified in accordance with the following international standards.

CE Certificate

ISO 13485:2016

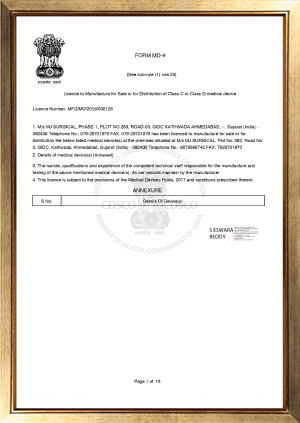

FDA (India)

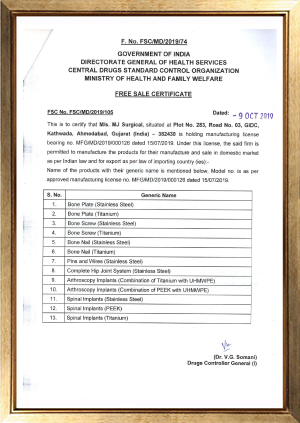

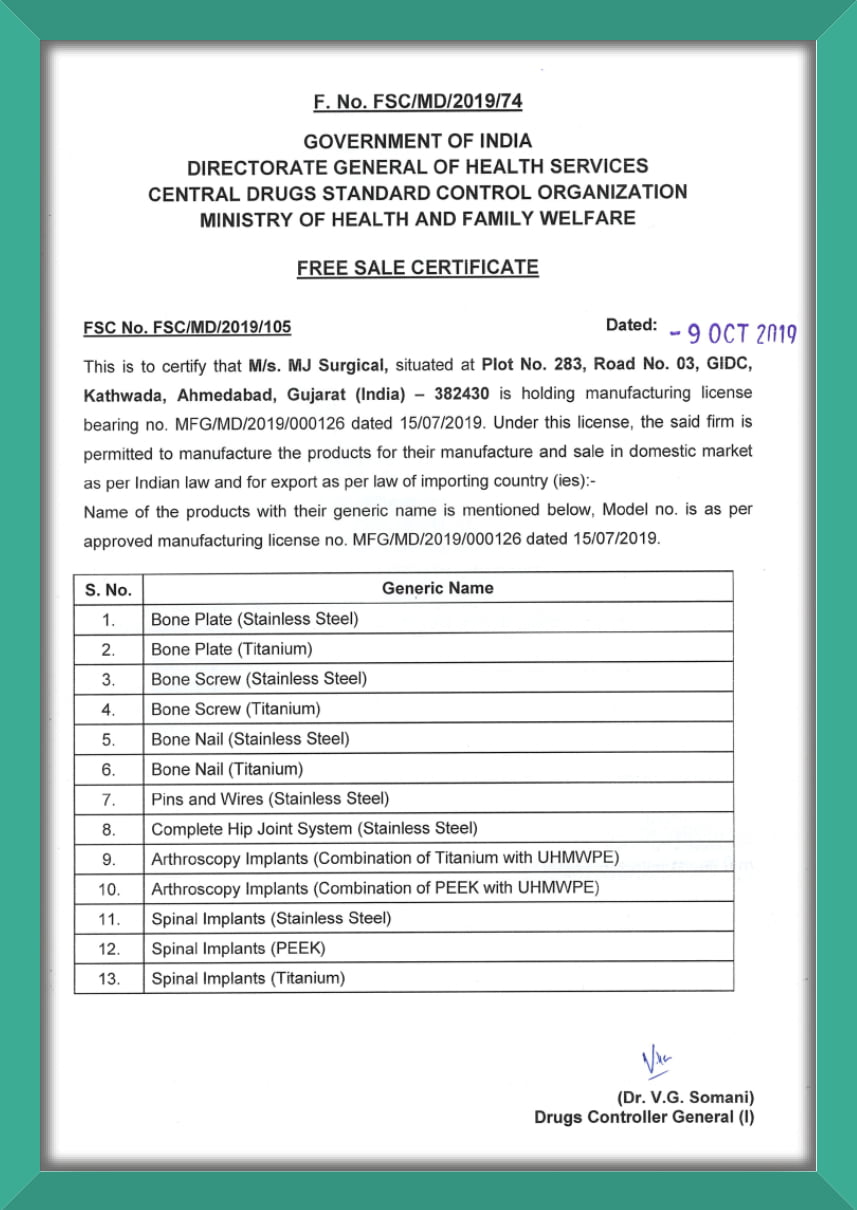

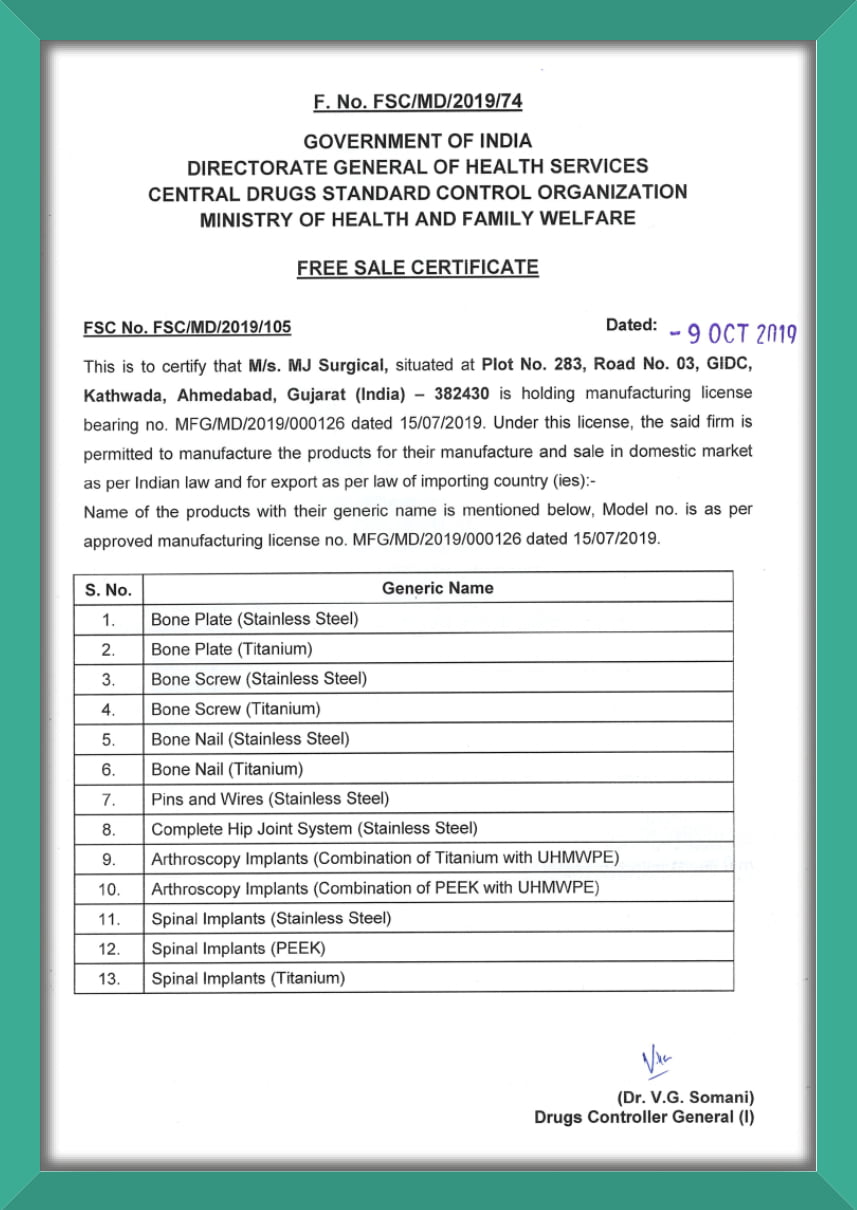

Free Sale Certificate

Certifications

MJ Surgical maintains a quality management system which is regularly certified in accordance with the following international standards.

MTIC Certificate

MRTC Certificate

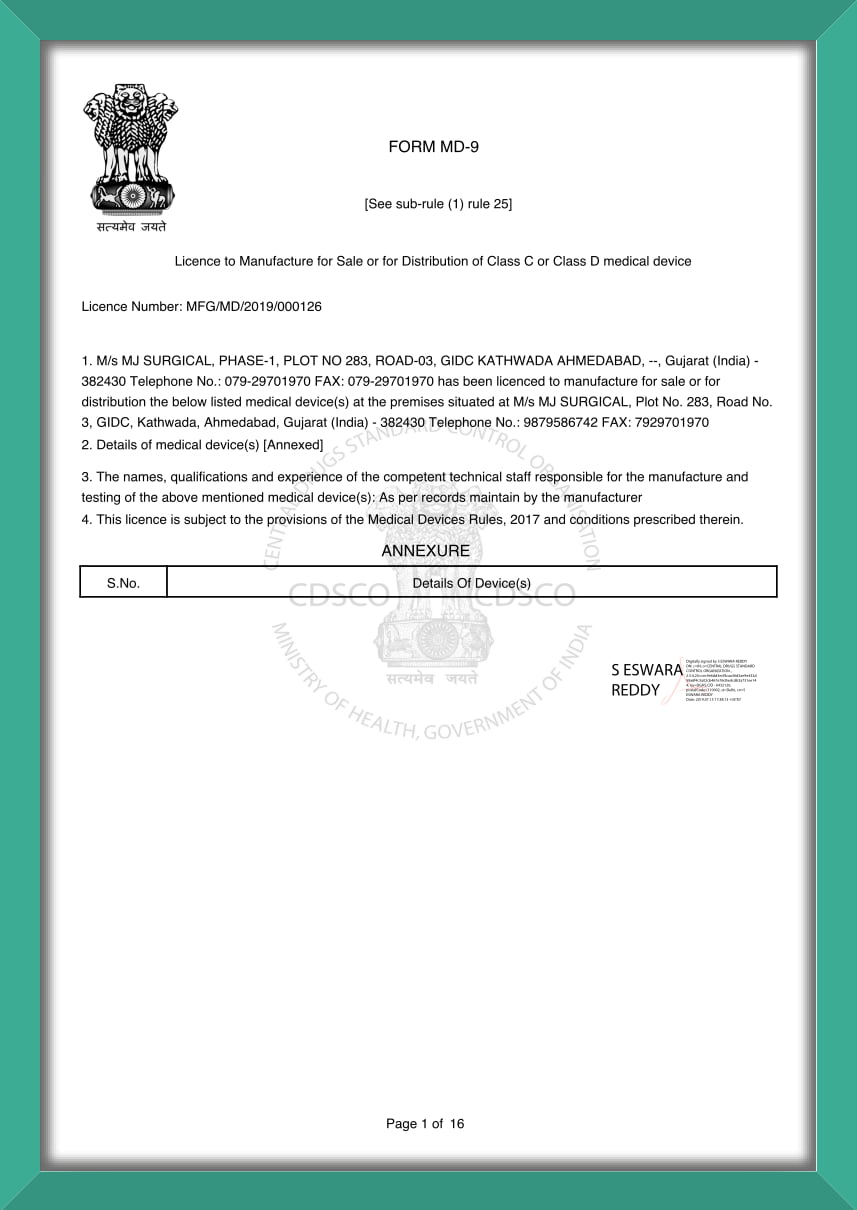

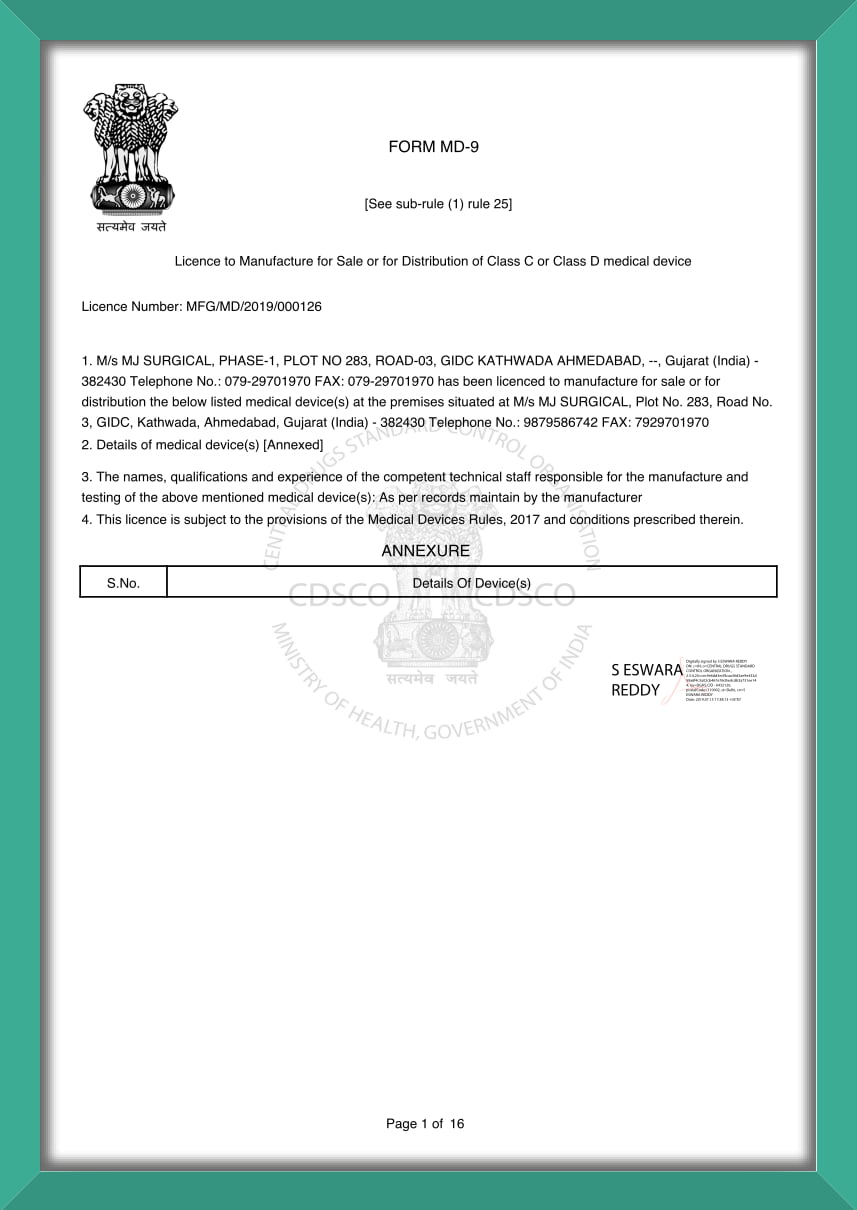

FDA (India)

Free Sale Certificate

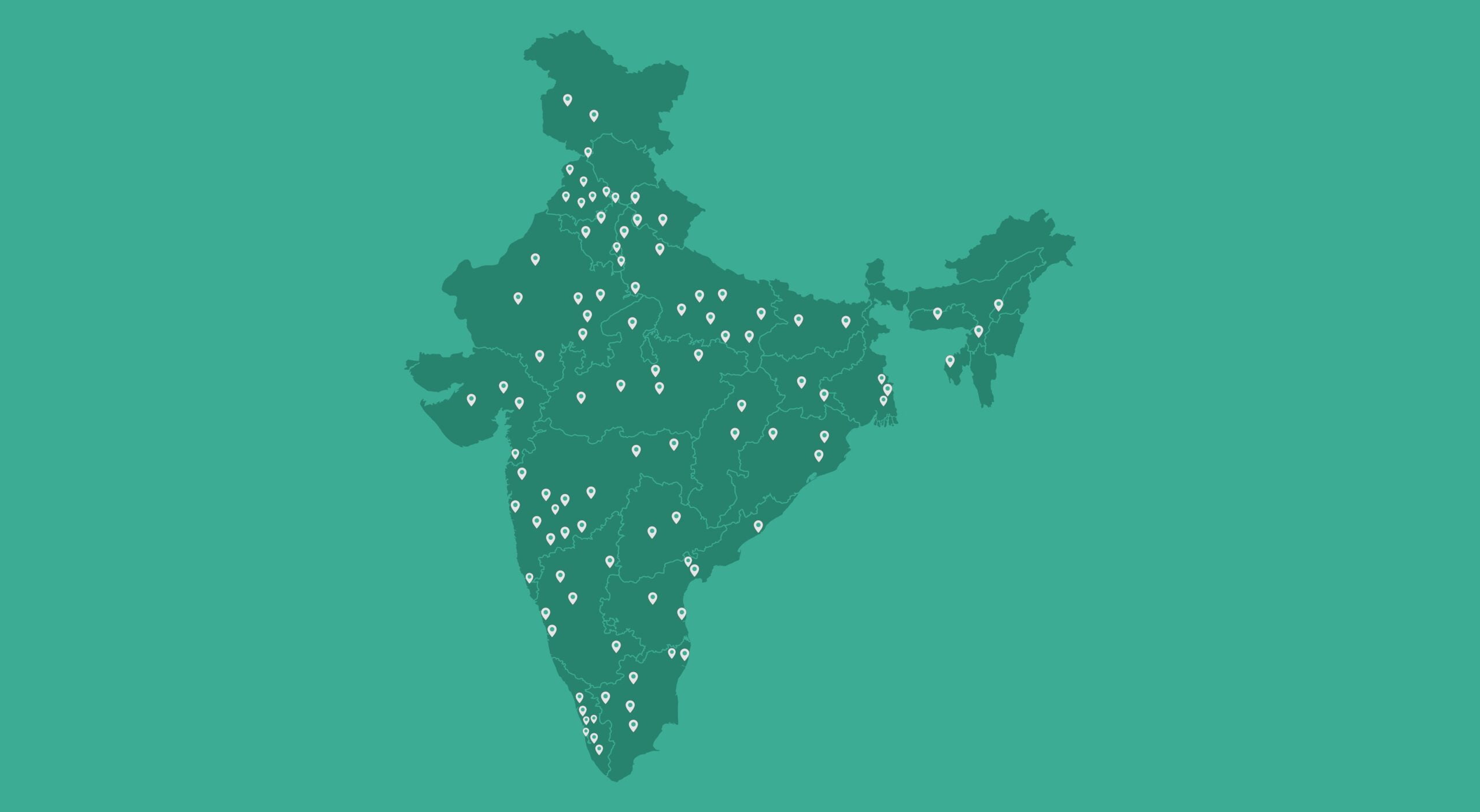

Our Presents

In a span of more than two decades, MJ Surgical has established its presence through direct and partner network globally. Our representatives and network partners are located in almost each state of the India providing products and services of MJ Surgical. Apart from domestic market, MJ Surgical is there in the Asia, Middle- East, Africa, Europe, North America, South America…

We invite business partners across any Global Location to share value based business opportunities.

Global Presents

Domestic Presents

MJ SURGICAL is India’s leading manufacturer, suppler and exporter of orthopedic Implants & Instruments based at Ahmedabad, Gujarat.

MJ SURGICAL has been able to establish its name as one of the most preferred and trusted brands by healthcare experts and vendors across the world. Our range and quality of the products have earned us the global repute and recognition in orthopedic implants and instruments.

MJ SURGICAL implants are made of stainless steel, titanium alloys and PEEK. The materials are tested for biocompatibility and safety according to EN ISO 10993 and EN ISO 14971. The chemical composition, mechanical properties, and the purity of the microstructure meet the requirements specified by international standards.

MJ SURGICAL aims at providing world class orthopedic implants and instruments at the affordable cost.

MJ SURGICAL has always been open to the innovations. Perhaps that’s the reason why we have been able to create a state of the art production unit with 15000Sq/Ft area at KATHWADA GIDC in Ahmedabad.

Our manufacturing unit comprises of the latest machineries imported from across the world. We are using CNC Mill Turn, CNC Multi-axis, VMC Multi-axis, CNC Turning, Wire EDM, Automated Buffing, Sand Blasting, Electropolishing, Titanium Anodizing, Ultrasonic Cleaning, and Laser Marking Machines..

Our team comprises highly motivated members like engineers, designers, product developers, machine operators, marketing team, logistics team, quality control team, R & D team, consultants and more!

Our senior management believes in the philosophy of driven by patients, focused by medical practitioners. We have always tried to develop products with international standards within the criteria of affordability.

Be it the top most management or the youngest member of the MJ family, one thing is common in all of us: ‘passion to achieve more and more milestones that makes the lives of patients healthier and happier day by day, minute by minute, moment by moment!’

MJ SURGICAL is globally represented by self or through our appointed representatives. We have been exporting our products to Europe, America, Africa, Asia and other major parts of the world. Nationally we cover almost all corners of the country. Export inquires are generated from various parts of the world for supply of different types and wide range of MJ SURGICAL products made out of exclusively products range.

Presently the global market situation is being assessed and the strategy is reorganized to suite the demands of the global requirement.One can find MJ SURGICAL at almost all leading national and international level seminars, conferences, exhibitions, conventions, gatherings and all type of ortho implant manufacturing related words and venues.

MJ Surgical maintains a quality management system which is regularly certified in accordance with the following international standards.

CE Certificate

ISO 13485:2016

FDA (India)